Critical Applications That Require Ergonomic Lifting Solutions

In the military and defense sectors, the products employed must demonstrate a high level of quality, dependability, and safety. This requirement is true for all materials, machines, and systems, including material handling equipment.

Material handling equipment finds applications in many military and defense operations, ranging from the loading and unloading of supplies to the transport of materials from one location to the next. In these often critical and sensitive situations, it’s important the lifting and positioning solutions are designed and manufactured to provide optimal performance without the risk of operator injury.

The following blog post discusses the importance of integrating ergonomic design into Mil-spec material handling equipment and provides examples of the equipment used in military and defense applications.

The Importance of Ergonomics in the Military and Defense Industries

In the workplace, the term “ergonomics” refers to the design and optimization of equipment and a facility’s layout to suit the employees. While it is generally used when referring to offices and warehouses, its principles can be applied to all industries, including military and defense.

Ultimately, the goal of ergonomic design is to make the workplace safer and more efficient. These benefits then translate to lower risk of operator injury, higher employee productivity, and greater overall morale. Within the military and defense industries, the use of ergonomic material handling systems result in the following:

Lower Risk of Injury to Life and Limb

Well-designed lifting and positioning equipment can accommodate large and heavy materials without significant risk to the machine operator. On the other hand, the wrong equipment can increase the risk of employees experiencing back injuries as a result of lifting, handling, or carrying objects.

Some of the factors that can cause back injury include:

- Awkward positioning or posture. When lifting heavy materials, the amount of force acting on the body and where it is concentrated depends on the lifter’s posture and lifting method. Improper lifting or carrying technique may result in excessive force acting on the back, which can cause injury.

- Continuous or excessive vibrations. During operation, powered hand tools often generate vibrational force. When used for significant amounts of time or under the wrong circumstances (e.g., in cold environments or by personnel with poor blood flow), the vibrations can cause muscular disorders, muscular spasms, vascular constriction, and other vibration-induced issues.

- Constant or extreme force. The National Institute for Occupational Safety and Health (NIOSH) recommends personnel lift no more than 51 lbs. However, many industry professionals regularly lift more than the recommended amount in their day-to-day activities. These heavier loads cause strain on the body.

- Repetitive movement. Operations involving repetitive movement continually put stress and strain on the same muscle groups. Over time, this can lead to inflammation, irritation, and other injuries.

Faster Operations

Material handling equipment allows workers to move supplies easily without resorting to manual methods. In doing so, it enables them to complete transportation and distribution operations much faster.

Better Accommodation of OSHA Regulations

OSHA regulations dictate safety requirements for workers. Ergonomic equipment generally integrates these standards to enhance worker and workplace safety.

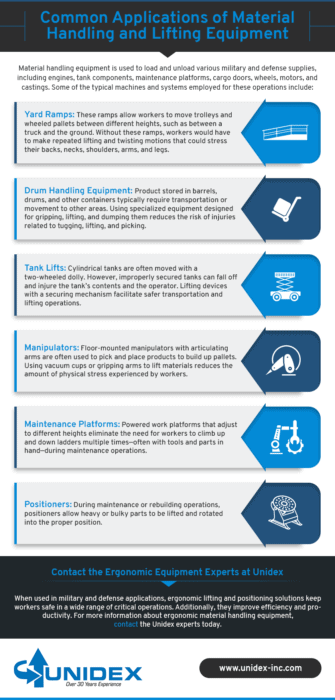

Common Applications of Material Handling and Lifting Equipment

Material handling equipment is used to load and unload various military and defense supplies, including engines, tank components, maintenance platforms, cargo doors, wheels, motors, and castings. Some of the typical machines and systems employed for these operations include:

Yard ramps: These ramps allow workers to move trolleys and wheeled pallets between different heights, such as between a truck and the ground. Without these ramps, workers would have to make repeated lifting and twisting motions that could stress their backs, necks, shoulders, arms, and legs.

- Drum handling equipment: Product stored in barrels, drums, and other containers typically require transportation or movement to other areas. Using specialized equipment designed for gripping, lifting, and dumping them reduces the risk of injuries related to tugging, lifting, and picking.

- Tank lifts: Cylindrical tanks are often moved with a two-wheeled dolly. However, improperly secured tanks can fall off and injure the tank’s contents and the operator. Lifting devices with a securing mechanism facilitate safer transportation and lifting operations.

- Manipulators: Floor-mounted manipulators with articulating arms are often used to pick and place products to build up pallets. Using vacuum cups or gripping arms to lift materials reduces the amount of physical stress experienced by workers.

- Maintenance platforms: Powered work platforms that adjust to different heights eliminate the need for workers to climb up and down ladders multiple times—often with tools and parts in hand—during maintenance operations.

- Positioners: During maintenance or rebuilding operations, positioners allow heavy or bulky parts to be lifted and rotated into the proper position.

Contact the Ergonomic Equipment Experts at Unidex

When used in military and defense applications, ergonomic lifting and positioning solutions keep workers safe in a wide range of critical operations. Additionally, they improve efficiency and productivity. For more information about ergonomic material handling equipment, contact the Unidex experts today.