ABOUT OUR CUSTOMIZED HYDRAULIC LIFTS & MATERIAL HANDLING SOLUTIONS

Material handling equipment and hydraulic lifts serve as a safe and efficient method of moving materials, pallets, and other challenging materials between floors. At Unidex, we offer durable, long-lasting products that are fully customizable to your requirements. Our solutions are capable of moving anything from small boxes under 100 lbs to large components weighing over 1,000 lbs.

No matter what industry you’re in, our knowledgeable team can help you obtain a product that addresses all of your application-specific needs. Our portable lifts are ideal for a multitude of environments, including warehouses, retail spaces, manufacturing facilities, laboratories, distribution centers, or anywhere else you would need to move materials.

TYPICAL MODIFICATIONS

At Unidex, we work closely with our clients to deliver personalized modifications that goes beyond off-the-shelf solutions. We offer many types of engineered-to-order equipment and products that can be easily modified with custom fixtures according to your specifications. If your application requires advanced material handling technology but your budget or timeframe is tight, we can ensure you receive the solution you need.

Material handling products not only improve a business’s operational efficiency but also provide a safer and more ergonomic workplace for employees. However, to work most effectively, they must be tailored to the needs of each workspace.

Our pallet lifts, workbenches, lift tables, carts, work positioners, and other specialized equipment can include the following modifications:

ENGINEERED-TO-ORDER

No matter what your project’s goals are, Unidex can develop an engineered-to-order lift solution that exceeds your expectations. All of the products we offer can be engineered-to-order with the expertise of our in-house R&D, engineering, and manufacturing teams. If you have a challenge that demands an innovative solution, we can develop a cost-effective customized product that meets all of your process requirements.

Some of the most common challenges our lifts are engineered to solve include:

REDUCING LABOR COSTS

STREAMLINING MATERIAL HANDLING PROCESSES

MINIMIZING WORKPLACE HAZARDS

MAKING MORE EFFICIENT USE OF A FACILITY’S FOOTPRINT

ELIMINATING LABOR-INTENSIVE GOODS TRANSPORTATION

LEAN MANUFACTURING SYSTEMS

For businesses that require worker interface and a constant level of assembly or transfer, Unidex offers lean manufacturing systems. Our custom-engineered solutions can minimize the floor space required for assembly processes, improve your quality control, and enhance your production efficiency. We provide a completely specialized service that begins with a material handling consultation followed by custom systems integration design and finally the development of your lean manufacturing system.

We manufacture an extensive range of standard and engineered-to-order ergonomic material handling equipment, all of which can be integrated into your lean manufacturing system. Every solution we create is fully customized to your requirements, including products that can withstand corrosive environments or sanitation processes. We are highly experienced in creating products that adhere to demanding industry standards, including stainless steel construction for cleanrooms or medical facilities.

HYDRAULIC LIFTS

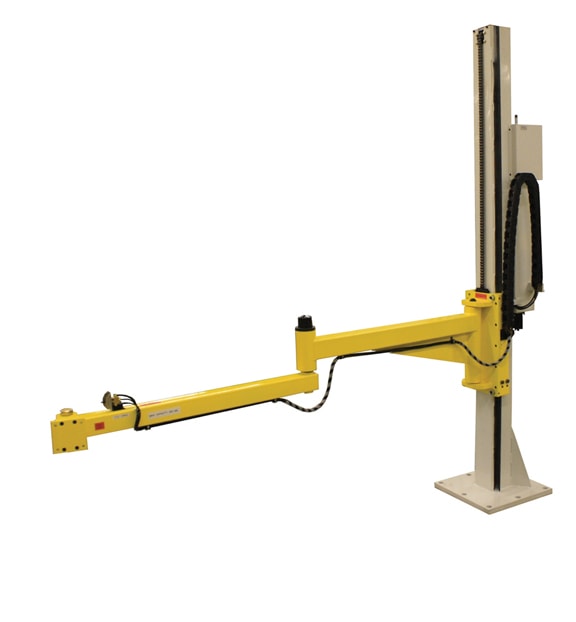

Hydraulic lifts are durable and robust solutions designed to handle heavy or bulky loads. While this equipment is common throughout numerous industries, demanding job sites within the assembly and repair areas, and warehouses are the most common. At Unidex, we offer hydraulic lifts in many configurations designed to increase safety and efficiency.

All hydraulic lifts rely on a hydraulic cylinder to lift, move, or position a load. Hydraulic cylinders come in different types: single, double-acting, and telescoping. Each type consists of a rod, piston, cylinder body, caps, and seals. Most hydraulic lift tables use a single-acting cylinder. In this type of cylinder, pressure pushes the rod out and gravity pressure returns it to its original position. This action from the cylinder converts hydraulic energy into linear movement.

Our extensive selection of hydraulic lifts includes solutions for mining applications, the aerospace industry, automotive environments, marine applications, and much more. The most common hydraulic lift products we offer include:

- Workbenches

- Foot Pedal Lifts

- Positioners

- Personnel Lifts

- Battery Lifts

- Medical Lifts

- Aircraft Lifts