Scissor Lift Alternatives

As a mobile work platform, the scissor lift has applications in construction, manufacturing, maintenance, and other industrial settings. These lifts effectively move and vertically elevate workers and equipment to assist in material handling and other tasks. Despite their usefulness, however, they do have several drawbacks.

Scissor lifts take up a lot of precious floor space, with closed base frames that typically only come standard in certain sizes. Their foot pedals are usually 10″ to 12″ above the ground, while an ergonomic design would instead have the pedal at step height, which is 8″ or less. Also, you operate the foot pedal manually, which requires time and energy from your workers. Even when pressing down hard on the pedals, the advertised platform rise height is often greater than what the equipment can effectively achieve, and the mechanism that raises and lowers the platform can loosen over time.

Scissor lifts can even pose a hazard to workers as they have pinch points that can crush or sever anything caught in the way of their moving parts. Fortunately, there are alternative options to scissor lifts that overcome these challenges. At Unidex, we offer custom capabilities for hydraulic or pneumatic lift tables and more. Read on to learn about our product offerings, and how scissor lift alternatives can benefit your operation.

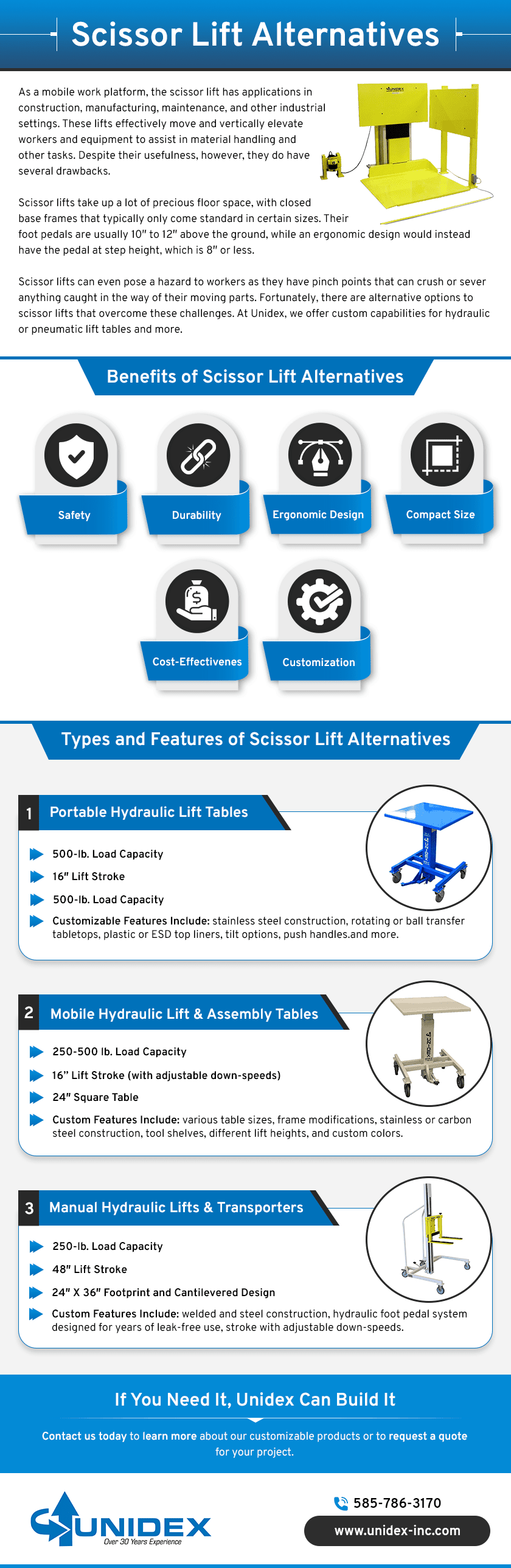

Benefits of Scissor Lift Alternatives

There are a variety of ergonomic and versatile scissor lift alternatives to meet the needs of diverse applications. They’re a flexible option, with an unobstructed area remaining between the legs and a top larger than the leg base. This enables workers to easily access racks, machinery, and other immobile components. They offer numerous advantages, such as:

- Safety. Without pinch points, scissor lift alternatives create a safer working environment. Proper ergonomics also reduce the risk of worker fatigue, strain, and injury.

- Durability. These products are constructed with quality materials and high-performance designs for years of leak-free use.

- Ergonomic design. Unidex’s foot pedals are just below 7″ from the ground for comfortable use. Ergonomic equipment reduces health risks for your employees as well as compensation claims and improves productivity by minimizing time lost to injury.

- Compact size. These space-saving alternatives have a small footprint to leave more room for other equipment and operations within your facility.

- Cost-effectiveness. As scissor lift alternatives are so customizable, you can purchase the model that meets your requirements without spending on features you don’t need. Also, they’re built to last, minimizing your maintenance and replacement costs over time.

- Customization. At Unidex, we specialize in the customization of scissor lift alternatives to ensure you get the right product for your application, no matter your specifications.

Types & Features of Scissor Lift Alternatives

Unidex doesn’t believe in one-size-fits-all equipment. That’s why our customizable options include pallet lift tables, pallet workstations, work positioners, and more. Our offerings include:

- PHQL Series “Quick Lifter” Portable Hydraulic Lift Tables.The standard models of these affordable yet high-performance tables feature a 500-lb. load capacity, 16″ lift stroke, and 24″ x 24″ table. Customizable options include stainless steel construction, rotating or ball transfer tabletops, plastic or ESD top liners, tilt options, push handles.and more.

- PH Series Mobile Hydraulic Lift & Assembly Tables. Unidex can configure these versatile 24″ square tables to have a variety of custom features, including various table sizes, frame modifications, stainless or carbon steel construction, and more. The standard models are available with a 250- or 500-lb. load capacity, 16″ lift stroke, and adjustable down-speeds. Customizable options include various table sizes and shapes, tool shelves, different lift heights, and custom colors.

- PHL Series Manual Hydraulic Lifts & Transporters.With a 24″ x 36″ footprint and cantilevered design, this series features welded steel construction, a high-performance hydraulic foot pedal system designed for years of leak-free use, a standard load capacity of 250 lbs., and a 48″ lift stroke with adjustable down-speeds. These are commonly used for component assembly, mobile staging, work positioning, and machine feeding.

We also offer TL Series Pallet Lifts for handling load capacities of 2,000 lbs., as well as PE Series Standard-Duty and Heavy-Duty Lifts with 200- and 1,000-lb. capacities, respectively.

If You Need It, Unidex Can Build It

Specializing in custom material handling equipment since 1991, Unidex serves clients all over the world with solutions for even the most unique or demanding of applications. Our scissor lift alternatives are durable, cost-effective, and safe, and they help you streamline your operations while creating a better work environment for your employees. Our ergonomic products are engineered to order, and we test them thoroughly to ensure proper functionality and reliable quality. Contact us today to learn more about our customizable products or to request a quote for your project.