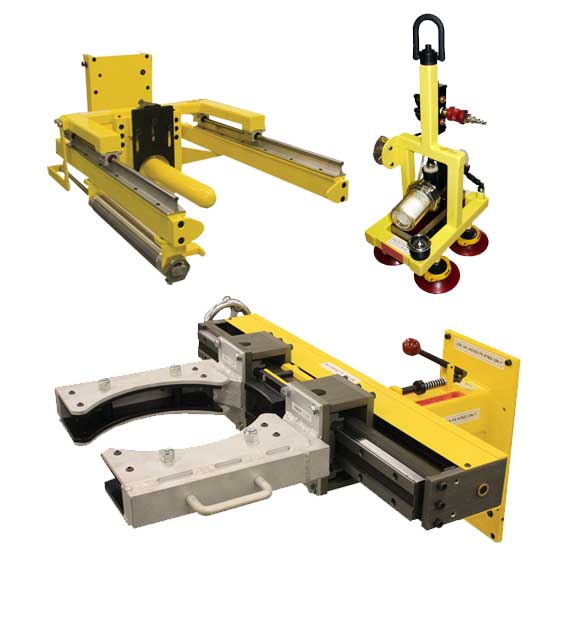

End Effectors & Tooling

Unidex can custom design manual, mechanical and powered end effectors to meet your exact positioning requirements. Custom designed engagement tooling allows for smooth, continuous movement throughout the work cycle and area. Unidex articulating arms and end effectors feature rugged welded tubular steel construction and an attractive and durable powder coat finish. In addition, each arm is free of vertical supports, permitting the arm to maintain the load attitude for reach-in and reach-under applications.

Applications for End Effectors and Tooling include bags, boxes, pails, drums, rolls, sheets, cabinets, frames, chassis, and other uses for lifting, rotating, pouring, or upending virtually any load. End effector styles include manual, clamp, cradle-trap, vacuum, magnetic, or other custom-designed grippers.