Manipulators and robot arms require end effectors to perform their designated tasks. They function by attaching to manipulator arms or a robot’s wrist, which enables this equipment to interact with a subject.

Manipulators and robot arms require end effectors to perform their designated tasks. They function by attaching to manipulator arms or a robot’s wrist, which enables this equipment to interact with a subject.

Operators often rely on gripper end effectors to lift and handle certain objects using robotic machinery, which is why these components are ideal for assembly, pick-and-place, and machine-tending applications. Operations use end effectors for robotics or manipulators to improve safety measures or eliminate safety concerns around the use of this machinery. In this post, we’ll provide an overview of the different end effector types, along with their various applications.

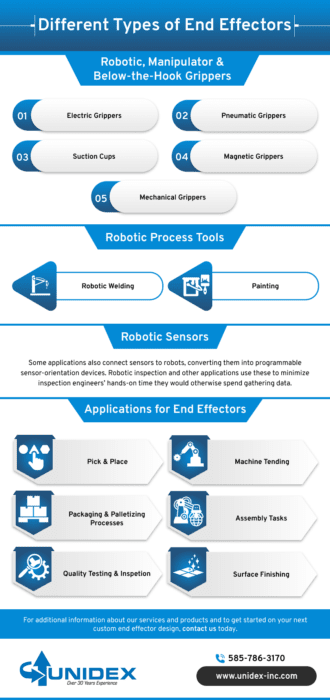

Different Types of End Effectors

Depending on the intended application, operations may use a variety of end effectors to perform certain tasks.

Click to Download

Click to DownloadRobotic Grippers

- Electric Grippers — Electric grippers use motor-driven fingers, which allow for easy control of position and speed. Many applications use adaptive electric end effectors, including machine tending, handling, and bin picking, among others.

- Pneumatic Grippers — These grippers use air to function, normally by forcing compressed air through a piston. Pneumatic grippers allow for angular or parallel movement.

- Suction Cups — Suction cups use a vacuum to pick up parts. Their simple design offers ample flexibility for material handling, along with cost-effectiveness. However, they are unable to handle perforated materials.

- Magnetic Grippers — These grippers feature a design that’s similar to suction cups, but they’re used specifically for handling ferrous material. Additionally, they eliminate the risk of dropping materials during power outages or air loss, and they don’t come with air costs. Their simple design also requires minimal maintenance.

- Mechanical Grippers — Non-powered mechanical grippers normally feature designs for specific types of parts. These grippers may include forks, hooks, or complex fingers that allow operators to clamp and rotate them.

Robotic Process Tools

- Robotic Welding — Applications often use robot arms with welding end effectors, which are most frequently found in the automotive industry. Because of their precision and consistency, robotic welding systems usually produce great results.

- Painting — The application of paint must be consistent and smooth, which often presents a challenge for human operators. In addition, these applications must protect against contamination in a controlled environment. Both of these factors make painting robots suitable for these conditions, allowing for high-quality paintwork while reducing the risk of contamination.

Robotic Sensors

Some applications also connect sensors to robots, converting them into programmable sensor-orientation devices. Robotic inspection and other applications use these to minimize inspection engineers’ hands-on time they would otherwise spend gathering data.

Applications for End Effectors

Many types of applications use robotics and manipulators with end effectors. Some potential applications include:

Pick & Place

These tasks involve picking up and placing objects in another location. Oftentimes, these applications require safe handling and precision when manipulating the object, regardless of the object’s material or its fragility.

Machine Tending

Machine tending entails overseeing equipment as it loads and unloads machines. It could also involve blow off, part inspection, sorting and packaging, and wash tasks.

Packaging & Palletizing Processes

These processes include high-speed and precision packaging assembly, pallet forming, and product loading, among other tasks. They’re particularly demanding in many applications due to the need to handle often fragile materials with a combination of efficiency and care.

Assembly Tasks

Assembly is a manufacturing process in which machinery assembles products by adding individual components one at a time in a specific sequence. In completing these tasks, the robot’s or manipulator’s end effector frequently handles objects of various shapes and sizes.

Quality Testing & Inspection

Following the manufacturing process, products require the application of consistent force and rigorous testing. While human workers may struggle to maintain consistent tension, pressure, and overall precision, it’s easy to program these tasks when using robotics with the appropriate end effectors.

Surface Finishing

Surface finishing tasks require adequate flexibility, which robotics and end effectors help achieve. Seeing as surface finishing is a particularly dirty task in the production process, it’s also ideal for automating with the right programmable machinery.

End Effectors & Tooling at Unidex

To meet the needs of any application, it’s important to select not only the right robotic and manipulator systems but also the right end effector. At Unidex, we offer custom mechanical, powered, and manual end effectors based on your individual requirements. Our clients choose Unidex because we offer custom solutions that consider the entire application, taking a holistic approach to solving a wide range of potential problems in the workspace.

For additional information about our services and products and to get started on your next custom end effector design, contact us today.

Comments are closed