Scissor Lifts vs. PH Lift Tables

Leave a CommentScissor Lifts vs. PH Lift Tables

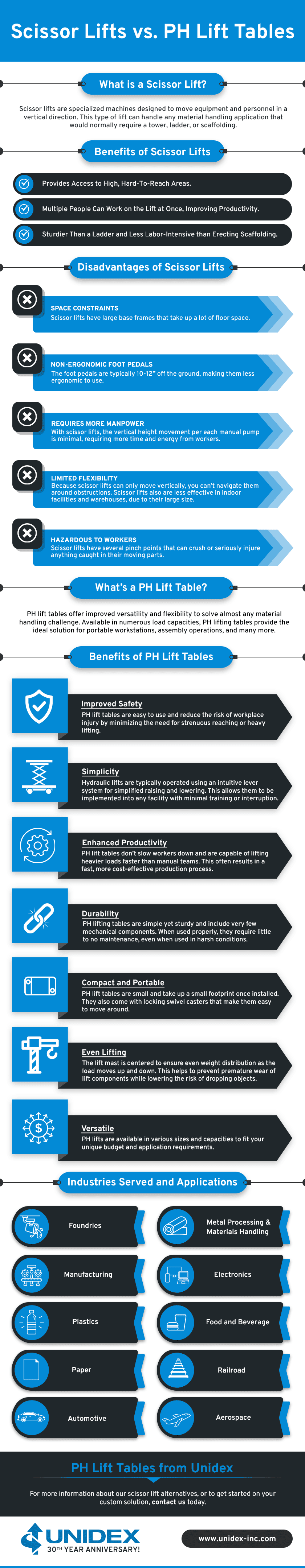

Scissor lifts work to vertically elevate workers and equipment for many material handling tasks, making them a popular option in numerous industries. Although scissor lifts can be useful in certain situations, they come with several drawbacks that may not make them the best option for your needs. As a suitable alternative, portable hydraulic (PH) lift tables offer enhanced flexibility and versatility. Here, we’ll dive into the different advantages, disadvantages, and applications of scissor lifts and PH lift tables to help you make the right decision.

Scissor Lifts vs. PH Lifting Tables

What is a Scissor Lift?

Scissor lifts are specialized machines designed to move equipment and personnel in a vertical direction. This type of lift can handle any material handling application that would normally require a tower, ladder, or scaffolding.

Benefits of Scissor Lifts

Scissor lifts offer various benefits, including:

- Provides Access to High, Hard-To-Reach Areas

- Multiple People Can Work on the Lift at Once, Improving Productivity

- Sturdier Than a Ladder and Less Labor-Intensive than Erecting Scaffolding

Disadvantages of Scissor Lifts

Despite their numerous benefits, scissor lifts come with some significant disadvantages such as:

- Space Constraints. Scissor lifts have large base frames that take up a lot of floor space.

- Non-Ergonomic Foot Pedals. The foot pedals are typically 10-12’’ off the ground, making them less ergonomic to use.

- Requires More Manpower. With scissor lifts, the vertical height movement per each manual pump is minimal, requiring more time and energy from workers.

- Limited Flexibility. Because scissor lifts can only move vertically, you can’t navigate them around obstructions. Scissor lifts also are less effective in indoor facilities and warehouses, due to their large size.

- Hazardous to Workers. Scissor lifts have several pinch points that can crush or seriously injure anything caught in their moving parts.

What’s a PH Lift Table?

PH lift tables offer improved versatility and flexibility to solve almost any material handling challenge. Available in numerous load capacities, PH lifting tables provide the ideal solution for portable workstations, assembly operations, and many more.

Benefits of PH Lift Tables

PH lift tables offer a wide range of benefits that make them a preferred alternative to scissor lifts. These benefits include:

- Improved Safety. PH lift tables are easy to use and reduce the risk of workplace injury by minimizing the need for strenuous reaching or heavy lifting.

- Simplicity. Hydraulic lifts are typically operated using an intuitive lever system for simplified raising and lowering. This allows them to be implemented into any facility with minimal training or interruption.

- Enhanced Productivity. PH lift tables don’t slow workers down and are capable of lifting heavier loads faster than manual teams. This often results in a fast, more cost-effective production process.

- Durability. PH lifting tables are simple yet sturdy and include very few mechanical components. When used properly, they require little to no maintenance, even when used in harsh conditions.

- Compact and Portable. PH lift tables are small and take up a small footprint once installed. They also come with locking swivel casters that make them easy to move around.

- Even Lifting. The lift mast is centered to ensure even weight distribution as the load moves up and down. This helps to prevent premature wear of lift components while lowering the risk of dropping objects.

- Versatile. PH lifts are available in various sizes and capacities to fit your unique budget and application requirements.

Industries Served and Applications

Due to their many advantages, PH lifting tables are used across various industries and applications, including:

- Foundries. Lift tables provide safe, even lifting of cast components and raw metals.

- Metal Processing & Materials Handling. These industries utilize PH lift tables to speed up the movement of finished products and heavy raw materials.

- Manufacturing. Manufacturers of all kinds rely on PH lift tables for use as build stations and to help workers manage loads quickly and safely.

- Electronics. This industry utilizes PH lift tables with electrostatic discharge (ESD) to assemble or move large electronics without damaging sensitive circuitry.

- Plastics. The plastics industry uses PH lift tables to manufacture and maintain molding equipment, as well as for moving large amounts of heavy plastic components.

- Food and Beverage. Food and beverage facilities use PH lift tables to load heavy shipments after production and handle heavy equipment.

- Paper. Packagers, printers, and paper manufacturers use PH lift tables to transport and position heavy reams of paper.

- Railroad. Lift tables are used throughout the railroad industry to safely move train car components, cargo, maintenance equipment, and rails.

- Automotive. Lift tables help mechanics and auto manufacturers when preparing or servicing vehicles.

- Aerospace. PH lift tables are used in the aerospace industry to move heavy components that are impossible to lift by hand. For example, they can position and load aircraft parts during maintenance, manufacturing, and other operations.

PH Lift Tables from Unidex

While scissor lifts can prove useful for certain applications, PH lift tables offer many more benefits that make them the preferred choice for various industries. At Unidex, we’ve been specializing in custom material handling equipment for over 30 years. Our PH lift tables are flexible, cost-effective, durable, and ensure a safer working environment for your employees.

For more information about our scissor lift alternatives, or to get started on your custom solution, contact us today.