Safety Tips While Using a Lift Table

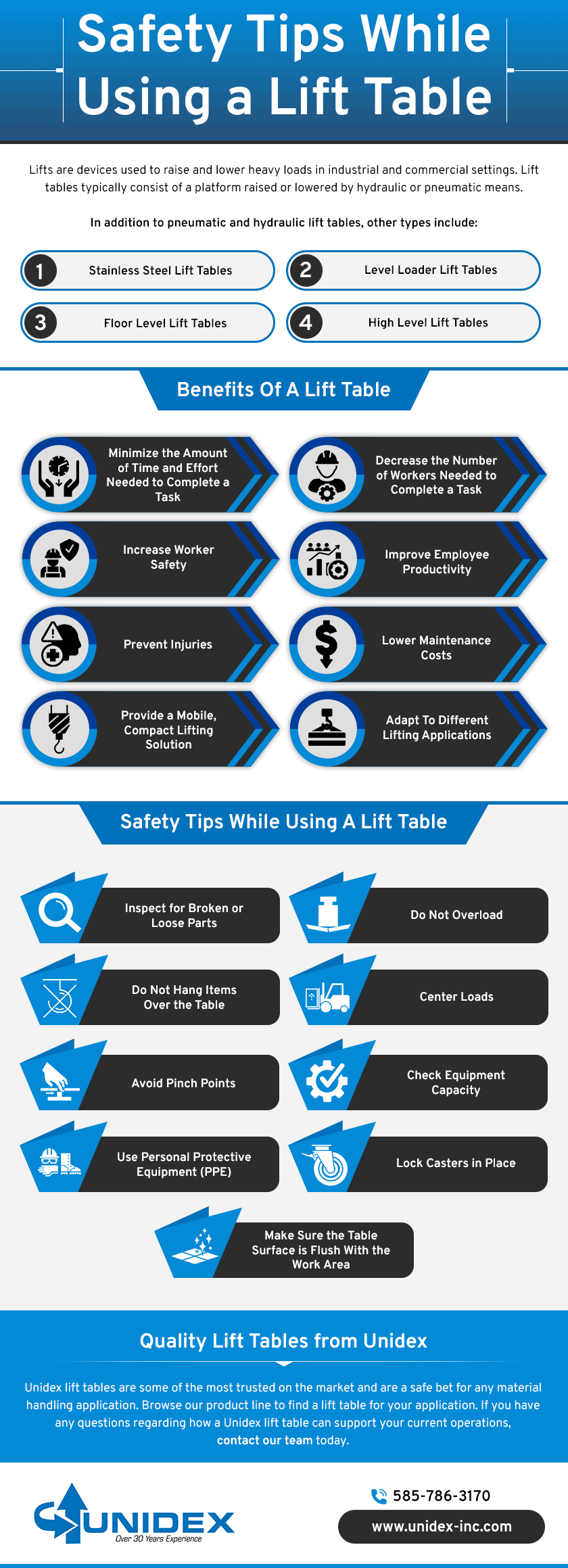

Comments Off on Safety Tips While Using a Lift TableLifts are devices used to raise and lower heavy loads in industrial and commercial settings. Lift tables typically consist of a platform raised or lowered by hydraulic or pneumatic means.

In addition to pneumatic and hydraulic lift tables, other types include:

- Stainless steel lift tables

- Level loader lift tables

- Floor level lift tables

- High level lift tables

- Scissor lift tables

Here we’ll discuss the benefits of lift tables, safety best practices, and what makes a good lift table for material handling applications.

Benefits of a Lift Table

Lift tables are an important piece of material handling equipment. They can help improve worker productivity and safety while reducing the risk of injuries. When used properly, a lift table can help to:

- Minimize the amount of time and effort needed to complete a task

- Decrease the number of workers needed to complete a task

- Increase worker safety

- Improve employee productivity

- Prevent injuries

- Lower maintenance costs

- Provide a mobile, compact lifting solution

- Adapt to different lifting applications

Safety Tips While Using a Lift Table

Here are some safety tips to bear in mind while using a lift table:

- Inspect for broken or loose parts. Before use, check for any damage or loose parts. If you notice any problems, don’t use the lift table and contact a qualified technician for repairs.

- Do not overload. Overloading the lift table can cause it to tip over or break, leading to serious injuries.

- Do not hang items over the table. This will create an unbalanced load and cause the table to tip over.

- Center loads. Ensure proper load placement by centering the load on the table.

- Avoid pinch points. Keep fingers and hands away from pinch points, especially on scissor lift tables. Raise or lower the platform slowly to avoid sudden movements.

- Check equipment capacity. Make sure to use the correct lifting equipment for a given environment. The table should have a strong surface and grip or traction. Also check that the lift table has sufficient load-bearing capacity for your desired application.

- Use personal protective equipment (PPE). Trained operators should supervise lifting and lowering operations. They should also wear appropriate PPE for added safety.

- Ensure proper balance. Wheel size and the tabletop need to be measured for correct balance.

- Lock casters in place. Lift tables have four swivel casters with locks so they can be locked in place when transferring product on and off and can be easily turned depending on direction.

- Make sure the table surface is flush with the work area. The leg base is slightly smaller than the top surface so that the lift table can be flush with the work area without gaps when transferring products on or off. This enhances the safety of the operation by reducing the chances of products falling between gaps.

What Makes a Good Lift Table

Not all lift tables are the same. A good lift table will have the following qualities:

- A sturdy platform that is level and steady

- Sufficient weight capacity

- Easy-to-use controls

- A compact design

- Wheels that make it easy to transport

- Durable construction

- Economical

- Versatility and efficiency in various applications

Why Unidex Lift Tables Are the Safest Choice

With over three decades of experience, Unidex has a proven track record of providing quality products that are safe and reliable.

All our lift tables are designed with safety, durability, and ease of use in mind. They come in light, standard, and heavy-duty options with different tilting, lifting, and rotating mechanisms for various industrial applications. We also offer a variety of customization options to ensure that our products meet the specific needs of our customers.

Quality Lift Tables From Unidex

Lift tables are valuable pieces of material handling equipment. By performing repetitive and potentially dangerous lifting tasks, lift tables reduce the risk of worker injury, allowing them to perform at their most productive. There are a few safety tips you should keep in mind while using a lift table, such as inspecting the table before use, not overloading the table, and using the proper lifting techniques. When selecting a lift table, it is important to choose one that meets your specific needs.

Unidex lift tables are some of the most trusted on the market and are a safe bet for any material handling application. Browse our product line to find a lift table for your application. If you have any questions regarding how a Unidex lift table can support your current operations, contact our team today.