Lift tables are adjustable surfaces used to raise, lower, and convey goods and materials within a facility or workspace. While lift tables are available in a wide range of materials, stainless steel is the material of choice for the food and pharmaceutical industries. Stainless steel is strong, corrosion-resistant, and easy to sanitize. It is ideal for sensitive operations that must meet rigorous health and safety standards established by the FDA and other regulatory bodies. By incorporating FDA-approved stainless steel lift tables into food and beverage and pharmaceutical operations, companies save time and money on cleaning, maintenance, and upkeep while eliminating the potential for cross-contamination due to surface imperfections and corrosion.

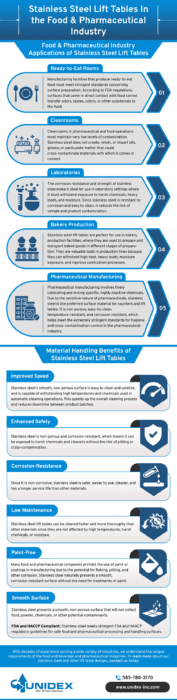

Food & Pharmaceutical Industry Applications of Stainless Steel Lift Tables

Stainless steel lift tables are an affordable and highly versatile option for a wide range of food and pharmaceutical applications, including:

- Ready-to-Eat Rooms: Manufacturing facilities that produce ready-to-eat food must meet stringent standards concerning surface preparation. According to FDA regulations, surfaces that come in direct contact with food cannot transfer odors, tastes, colors, or other substances to the food.

- Cleanrooms: Cleanrooms in pharmaceutical and food operations must maintain very low levels of contamination. Stainless steel does not create, retain, or impart oils, grease, or particulate matter that could cross-contaminate materials with which it comes in contact.

- Laboratories: The corrosion resistance and strength of stainless steel make it ideal for use in laboratory settings where it must withstand exposure to harsh chemicals, heavy loads, and moisture. Since stainless steel is resistant to corrosion and easy to clean, it reduces the risk of sample and product contamination.

- Bakery Production: Stainless steel lift tables are perfect for use in bakery production facilities, where they are used to prepare and transport baked goods in different stages of preparation. They are valuable tools in production lines because they can withstand high heat, heavy loads, moisture exposure, and rigorous sanitization processes.

- Pharmaceutical Manufacturing: Pharmaceutical manufacturing involves finely calibrating and mixing specific, highly reactive chemicals. Due to the sensitive nature of pharmaceuticals, stainless steel is the preferred surface material for counters and lift tables. It is non-porous, easy-to-clean, temperature-resistant, and corrosion-resistant, which helps meet the extremely stringent standards for hygiene and cross-contamination control in the pharmaceutical industry.

Material Handling Benefits of Stainless Steel Lift Tables

Stainless steel lift tables offer a wide range of benefits for material-handling operations in the food and pharmaceutical industry, including:

- Improved Speed: Stainless steel’s smooth, non-porous surface is easy to clean and sanitize, and is capable of withstanding high temperatures and chemicals used in automatic cleaning operations. This speeds up the overall cleaning process and reduces downtime between product batches.

- Enhanced Safety: Stainless steel is non-porous and corrosion-resistant, which means it can be exposed to harsh chemicals and cleaners without the risk of pitting or cross-contamination.

- Corrosion-Resistance: Since it is non-corrosive, stainless steel is safer, easier to use, cleaner, and has a longer service life than other materials.

- Low Maintenance: Stainless steel lift tables can be cleaned faster and more thoroughly than other materials since they are not affected by high temperatures, harsh chemicals, or moisture.

- Paint-Free: Many food and pharmaceutical companies prohibit the use of paint or coatings in manufacturing due to the potential for flaking, pitting, and other corrosion. Stainless steel naturally presents a smooth, corrosion-resistant surface without the need for treatments or paint.

- Smooth Surface: Stainless steel presents a smooth, non-porous surface that will not collect food, powder, chemicals, or other potential contaminants.

FDA and HACCP Compliant: Stainless steel meets stringent FDA and HAACP regulatory guidelines for safe food and pharmaceutical processing and handling surfaces.

Quality Stainless Steel Lift Tables by Unidex

Whether you need a lightweight and mobile stainless steel lift table for pharmaceutical manufacturing or a heavy-duty table for your baking operation, the experts at Unidex can help you find the perfect lift table solution. With decades of experience serving a wide variety of industries, we understand the unique requirements of the food and beverage and pharmaceutical industries.

To learn more about our stainless steel and other lift table designs, contact us today!