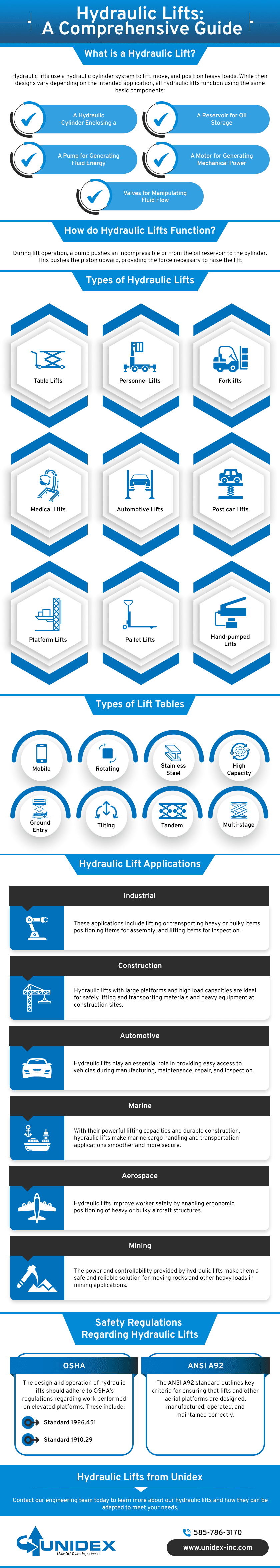

Hydraulic Lifts: A Comprehensive Guide

Hydraulic lifts are powerful devices used to handle heavy loads in manufacturing warehouses, construction sites, and other industrial environments. Available in a range of designs, these ergonomic lifting solutions enhance the safety and efficiency of various material handling tasks. Below, we provide a general overview of hydraulic lifts, including the following topics:

- What is a hydraulic lift?

- How do hydraulic lifts function?

- What are the types of hydraulic lifts?

- What are the types of hydraulic lift tables?

- Hydraulic lift applications

- Safety regulations regarding hydraulic lifts

What is a Hydraulic Lift?

Hydraulic lifts use a hydraulic cylinder system to lift, move, and position heavy loads. While their designs vary depending on the intended application, all hydraulic lifts function using the same basic components:

- A hydraulic cylinder enclosing a piston

- A reservoir for oil storage

- A pump for generating fluid energy

- A motor for generating mechanical power

- Valves for manipulating fluid flow

How do Hydraulic Lifts Function?

During lift operation, a pump pushes an incompressible oil from the oil reservoir to the cylinder. This pushes the piston upward, providing the force necessary to raise the lift. Once the desired height is reached, the pump is switched off and the lift is held securely in position by the oil trapped within the cylinder. To return the lift to its original position, a valve is opened to release oil back into the reservoir, and the piston is lowered by gravitational force.

Depending on the position, size, and operation of the cylinder, hydraulic lifts can be categorized as holed or hole-less systems. With holed hydraulic systems, the cylinder extends into a hole in the ground at a distance that is equivalent to the lift’s maximum vertical travel height. In contrast, hole-less hydraulic systems use a direct-acting piston to raise the lift, eliminating the need for a hole.

Hydraulic lifts consist of several interacting systems:

- Circuits. A hydraulic circuit is designed to control the flow and pressure of the liquid.

Pump. Hydraulic pumps are responsible for converting mechanical energy to hydraulic energy. The mechanical action of the pump creates a vacuum at the inlet. This forces the liquid to move from the reservoir to the inlet line, then through the outlet to the hydraulic system. - Motor. The hydraulic motor is a rotary actuator that converts hydraulic energy into torque and rotation.

- Cylinder. The cylinder converts hydraulic fluid energy into force and creates pressure in the fluid.

- Piston. The hydraulic piston, which is housed within the cylinder, moves upward in response to fluid pressure.

- Fluid. The hydraulic fluid allows power to be transferred throughout the system. While water and mineral oil are the most common hydraulic fluids, other options include:

- Glycol ether

- Organophosphate ester

- Polyalphaolefin

- Propylene glycol

- Silicone oil

Types Of Hydraulic Lifts

Hydraulic lifts are available in several types, each of which is optimized to meet specific load, safety, and mobility requirements. These include:

- Table lifts. Available in scissor or column-type designs, table lifts are ideal for lifting heavy loads across relatively short vertical distances.

- Personnel lifts. Personnel lifts are designed to safely raise personnel above ground level for maintenance, stocking, and other activities. Lightweight and portable, these lifts are suited for applications in which space is limited or weight is a concern.

- Forklifts. Forklifts are powerful devices that lift and transport heavy loads in warehouses, construction sites, and other industrial settings.

- Medical lifts. In the medical industry, medical lifts allow patients with limited mobility to be easily and safely moved by caregivers.

- Automotive lifts. Automotive lifts are designed to elevate vehicles to a comfortable working height for maintenance and repair tasks.

- Post car lifts. Post car lifts feature sturdy symmetrical columns positioned directly across from one another. This design aligns the vehicle’s center of gravity with the lift, ensuring that the load is evenly distributed across the columns, carriage, and bearings.

- Platform lifts. Platform lifts feature a supportive platform that is raised and lowered using crisscrossing braces. These lifts are useful for ceiling construction, cable wiring, and other tasks performed at elevated levels.

- Pallet lifts. Pallet jacks are used to lift and transport pallets and palletized loads in warehouses and trailers.

- Hand-pumped lifts. Designed for manual operation, hand-pumped lifts utilize a hydraulic hand pump to raise and lower loads.

Types of Hydraulic Lift Tables

Hydraulic lift tables safely raise and lower loads in heavy-duty material handling processes. Types of lift tables include:

- Mobile. Mobile lift tables are portable solutions for raising and accurately positioning heavy loads. Commonly used in warehouses and manufacturing plants, they help prevent strains and injuries related to the handling and inspection of heavy or bulky items.

- Rotating. Ideal for assembly applications, rotating lifts are equipped with a rotating top that allows easy access from multiple sides.

Low profile. With their low collapsed height, low profile lift tables allow for ergonomic lifting of heavy loads from the floor. Their design also provides easy access for pallet jacks. - Stainless steel. Stainless steel lift tables offer a durable and corrosion-resistant solution for handling loads in corrosive or harsh industrial environments.

- High capacity. Ideal for large loads and heavy cargo, high-capacity lift tables feature a robust and durable platform with a wide base to maximize stability.

- Ground entry. Ground entry lift tables provide access to pallet jacks for easy loading and unloading. Loads can also be positioned to various ergonomic working heights for inspection, maintenance, and other tasks.

- Tilting. Tilting lift tables feature lift heights and tilt angles that can be independently controlled, making them great for applications requiring precise positioning of large loads.

- Tandem. Tandem lift tables incorporate two standard base frames connected by a single platform. This design provides increased stability and safety when handling long or wide loads.

- Multi-stage. Multi-stage lift tables are light-capacity units featuring a small platform supported by two stacked pairs of scissor legs. This allows vertical travel to be maximized while maintaining a small, compact design.

Hydraulic Lift Applications

Hydraulic lifts support essential material handling applications in several industries, including:

- Industrial. Electro-hydraulic technology improves the speed and precision of lifts, allowing them to provide safe and smooth load control in various industrial applications. These applications include lifting or transporting heavy or bulky items, positioning items for assembly, and lifting items for inspection.

- Construction. Hydraulic lifts with large platforms and high load capacities are ideal for safely lifting and transporting materials and heavy equipment at construction sites.

- Automotive. In the automotive industry, hydraulic lifts play an essential role in providing easy access to vehicles during manufacturing, maintenance, repair, and inspection.

- Marine. With their powerful lifting capacities and durable construction, hydraulic lifts make marine cargo handling and transportation applications smoother and more secure.

- Aerospace. In aerospace applications, hydraulic lifts improve worker safety by enabling ergonomic positioning of heavy or bulky aircraft structures. For example, high-capacity hydraulic lifts provide vertical and lateral access to jet engines, wings, and other components for assembly, cleaning, or repair activities.

- Mining. The power and controllability provided by hydraulic lifts make them a safe and reliable solution for moving rocks and other heavy loads in mining applications.

Safety Regulations Regarding Hydraulic Lifts

Given the amount of force supplied by hydraulic lifts, it is important to abide by strict safety guidelines during equipment use. Relevant hydraulic lift safety certifications and regulations include:

- OSHA. The design and operation of hydraulic lifts should adhere to OSHA’s regulations regarding work performed on elevated platforms. These include:

- Standard 1926.451. This standard addresses general requirements for guardrail systems and other appropriate forms of fall protection.

- Standard 1910.29. That standard addresses personal protective equipment for protection against falling objects as well as guardrail design guidelines.

- ANSI A92. The ANSI A92 standard outlines key criteria for ensuring that lifts and other aerial platforms are designed, manufactured, operated, and maintained correctly.

Aerial lift certifications. OSHA aerial lift certifications require lift operators to pass an OSHA-certified training course regarding safe lift operation and maintenance.

Hydraulic Lifts from Unidex

Hydraulic lifts increase the efficiency of industrial material handling tasks while creating a safer work environment for employees. At Unidex, our customer-focused approach allows us to create custom ergonomic material handling solutions that fit the unique requirements of each application. Featuring various designs and load capacities, our hydraulic lifts improve workflow efficiency and reduce manual labor in a range of demanding work environments.

Contact our engineering team today to learn more about our hydraulic lifts and how they can be adapted to meet your needs.