How EH Positioning Systems Power the Aerospace Industry

Leave a CommentHow EH Positioning Systems Power the Aerospace Industry

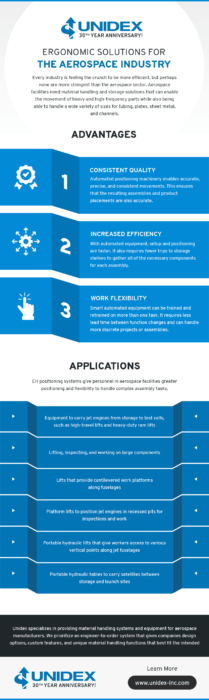

Every industry is feeling the crunch to be more efficient, but perhaps none are more stringent than the aerospace sector. Aerospace companies need to be able to easily access and store thousand of unique parts, each type with wildly different dimensions and storage condition demands.

Static storage and pick shelving are basic solutions, but they take up a lot of space. More complex systems like AS/RS systems, carousels, and gravity flow picking racks are more efficient. Aerospace facilities need material handling and storage solutions that can enable the movement of heavy and high-frequency parts while also being able to handle a wide variety of sizes for tubing, plates, sheet metal, and channels.

Advantages for Improved Efficiency and Productivity

With more advanced material handling solutions in place, personnel can easily access vertical and lateral storage spaces and use machinery to move the actual equipment to its destination. Reducing workplace accidents increases employee productivity, reduces turnover, and also reduces the costs of paying for medical fees and temporary staff. It also lets people work faster throughout the entire day.

Adding positioning tools to the system further increases its efficiency. These solutions allow workers to rotate airplane subassemblies, move them, and easily assemble or inspect the parts.

Three key benefits of positioning systems specifically include:

- Consistent quality. Automated positioning machinery enables accurate, precise, and consistent movements. This ensures that the resulting assemblies and product placements are also accurate.

- Increased efficiency. With automated equipment, setup and positioning are faster. It also requires fewer trips to storage shelves to gather all of the necessary components for each assembly. EH systems create even more efficiency because they reduce the amount of direct labor per assembly.

- Work flexibility. Smart automated equipment can be trained and retrained on more than one task. It requires less lead time between function changes and can handle more discrete projects or assemblies.

Common Applications

The aerospace industry has unique demands that must be considered when sourcing material handling and lifting equipment. These demands include the size of very large and heavy aircraft components, the weight of assembled parts like jet engines, and the complexity of electronic configurations. Some of the most common applications of specialized EH positioning systems include:

- Equipment to carry jet engines from storage to test cells, such as high-travel lifts and heavy-duty ram lifts

- Lifting, inspecting, and working on large components

- Lifts that provide cantilevered work platforms along fuselages

- Lightweight lifts for manual positioning

- Platform lifts to position jet engines in recessed pits for inspections and work

- Portable hydraulic lifts that give workers access to various vertical points along jet fuselages

- Portable hydraulic tables to carry satellites between storage and launch sites

Custom Aerospace Solutions from Unidex

EH positioning systems give personnel in aerospace facilities greater positioning and flexibility to handle complex assembly tasks. These systems can help workers operate on and near heavy and large machinery with reduced risks for injury. They also allow facilities to run more efficiently, have faster tool setup, and have more high-quality, precise arrangements.

Unidex specializes in providing material handling systems and equipment for manufacturers in a variety of challenging industries across North America. Since 1989, our company has concentrated on creating customized material handling solutions that meet unique challenges. We prioritize an engineer-to-order system that gives companies design options, custom features, and unique material handling functions that best fit the intended application.

Contact us today to learn more about our material handling systems and positioning systems for aerospace industries.